Septic Tank Replacement Schemes

In some countries more than 90 percent of households are without a connection to a sewer or whose sewerage infrastructure has failed due to age or poor maintenance.

Most of these areas have not installed conventional gravity systems due to the high costs involved. The town may be on very flat land or a high water table that would require very deep gravity mains causing not only a high maintenance cost but also a high construction cost.

Deep gravity lines may be impossible in certain areas because of the wide trenching interfering with homes, trees or other services. Vacuum sewers provide an ideal solution.

FLOVAC has worked closely with Water Authorities in coming up with cost effective ways of servicing communities by removing aging septic tanks and installing vacuum systems. Some state programs are under way to assist communities in funding sewerage systems and see vacuum systems as a cost effective way of providing this service.

In some areas where vacuum sewers are now being installed it is due to the collapse of ageing gravity sewerage infrastructure as in the case of Christchurch in New Zealand whose systems failed after massive Earthquakes in 2011 and 2012. Read More

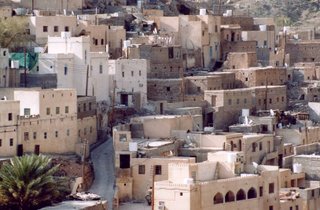

Brunei

Low Cost Solution

Vacuum sewer systems almost always cost less to install and less to maintain than traditional gravity systems, and certainly less than pressurized systems with grinder pumps if more than 100 houses are involved.

FLOVAC’s system does not use grinder pumps. In fact, the system does not use any electricity outside its central vacuum station which is very similar to a standard lift station, though safer and cleaner.

Reduced Construction Costs

Vacuum uses small diameter PVC or PE pipes and shallow burial depths. The resulting narrow, shallow trenches greatly reduce the digging, danger, disruption, and dewatering required for larger, deeper trenches.

In addition, inflow and infiltration, and ex filtration are eliminated. Since there are no manholes, entry into a confined space is not an issue.

Save on Treatment Costs

Vacuum sewers can save you money at your treatment plant because they transport wastewater very quickly in a mixture of two parts of air to each part of water.

As a result, the wastewater does not become septic during transport, and its aerobic when it arrives at the treatment plant. This eliminates odour during transport, and speeds processing at the treatment facility.

Importantly infiltration cannot occur and so there is no need to treat stormwater as it can be used to replenish potable water supplies

Long Life, Low Maintenance

Vacuum Sewers are installed with a design life of over 100 years. The vacuum interface valves have a design life of 50 years with very little maintenance required.

Operators say that vacuum sewers have a much lower long term maintenance cost due to the fewer number of pump stations required. That pipework is only installed at minimum cover is also a major factor in long term cost savings.

Environmentally Friendly

Due to negative pressure in the vacuum mains, effluent cannot escape into the environment from a vacuum system.

Should a leak occur, it would allow air into the pipe and would be detected immediately, and an alarm would be sent to operating personnel.

Simple Design

Even though vacuum systems are very simple, we work closely with client engineers during the design phase of each installation.

We offer assistance with piping profiles, vacuum station design, standard details, and sample specifications.

We will also review all plans and specifications.

FLOVAC

Flovac is the world's leading vacuum sewerage engineering, supplier and operation company.

Primer de Maig 4 Street

08980, Barcelona

Spain

CONTACT US

COPYRIGHT © 2021 FLOVAC - THE GREEN FUTURE OF SEWERAGE