Vacuum Sewer System Design

- 23 October, 2020

Project Design Process

At Flovac, we are aware of the importance of local knowledge of the clients and the specific projects we have to work in. For this reason, Flovac’s engineers work closely with customers with training on how to design the system, checking all calculations and assisting with the full process of the project. The planning of any vacuum sewerage project usually follows the following structure:

- Design Flows.

- Project Service Area.

- Catchment Area Determination by Vacuum Station.

- Vacuum Station Location.

- Locate Collection Pits.

- Locate the Vacuum Mains.

- Size the Vacuum Mains.

- Locate the Division Valves.

- Design Long Sections.

- Vacuum Station.

Customization of Each Project

At Flovac we know that each project is different based on its condition and characteristics. There is no “one design fits all” approach that can be taken. This is why we offer a personalized and adapted design for each project in order to guarantee an effective and successful installation.

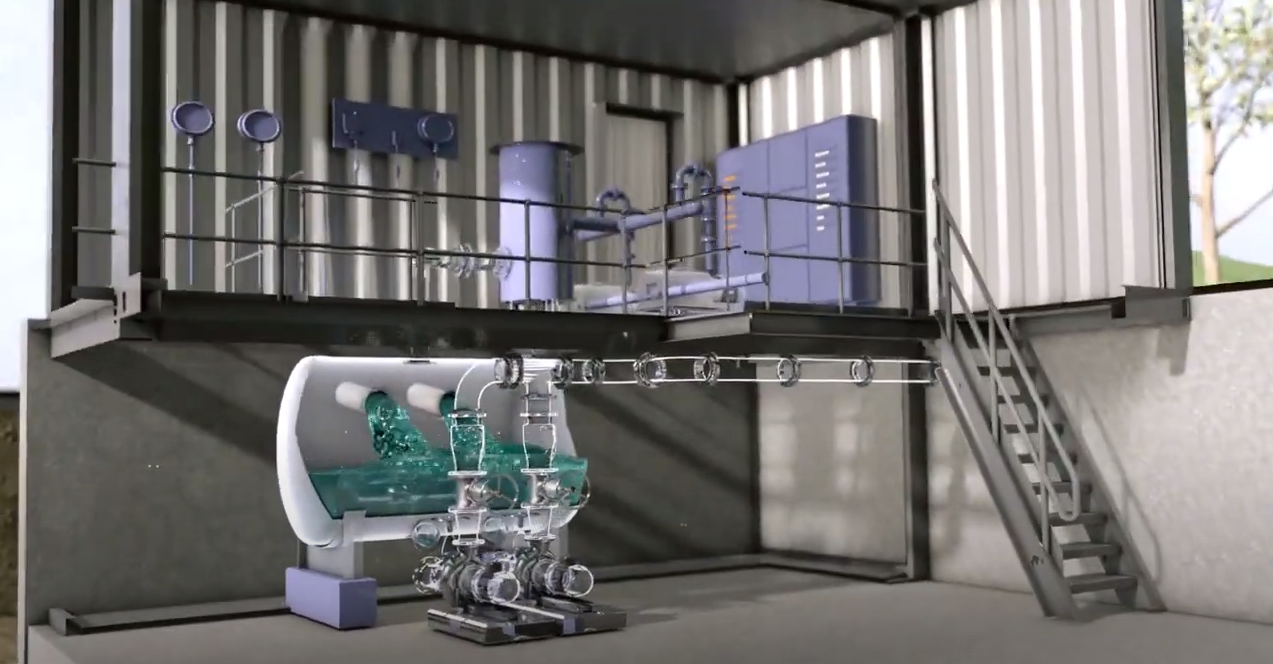

Flovac Vacuum Station

Over the years, design rules have changed and new technologies have emerged. Our long career has allowed us to incorporate all these improvements over the years and offer now the most innovative vacuum technology.

Master Planning Design

Ensuring proper planning is vital when designing a vacuum sewerage system. Any mistake in said planning could lead do problems such as excess flows, undersized mains, undersized vacuum stations and treatment plants, high power use, flooding and overflows. In the worst case, it could even lead to system collapses. For this reason, a well-understood system from a planning perspective is key to preventing future complications. At Flovac we guarantee an excellent study prior to any installation.

Master Plan Information

When managing a new project or an extension request, we always make sure to previously check a few vital aspects. These would be:

Check if the master plans properly updated with as-constructed data. What flow rates were originally designed for in the system and what are the current flow rates. If densities have changed. What are the calculated head losses on the vacuum lines. If the right emergency storage is being allowed for. If the original design called for a pump station upgrade at some future population density or flow rate. And lastly, if there are other areas that could now be accommodated.

Operational Knowledge is Key

Operational knowledge is key to ensure a proper functioning of the system. If we have a good master plan in place, a request for an extension or sub division can happen fairly quickly. The one area that many designers forget is in knowing how well the system is currently operating. At Flovac, our engineers always require approval from our operational groups prior to any modification to ensure an up-to-date knowledge of the status of our installations at any time.

Project Development Process

It is important to know how vacuum systems work in order to understand the planning of a project. The first step is to see if a vacuum system would be best suited for your project, or a combination of technologies. The second step is to send us a layout of your project, whether it is a septic tank replacement scheme, a new land development, a marina or something else where you may need a vacuum solution. Lastly, tell us the flow rates you would like us to use and where the sewage should be sent to.

At Flovac we will work with you on the costings and whole of life costs, including operational costs. And then, we will work with you on the full design and installation of the system. Please contact us if you need any further information.

Master Planning a Development Project

Get our news

Temas

Archives

FLOVAC

Flovac is the world’s leading vacuum sewerage engineering, supplier and operation company.

Primer de Maig 4 Street

08980, Barcelona

Spain

CONTACT US

COPYRIGHT © 2021 FLOVAC - THE GREEN FUTURE OF SEWERAGE