Flovac vacuum mains, the safest technology

- 8 January, 2021

What are the characteristics of vacuum mains?

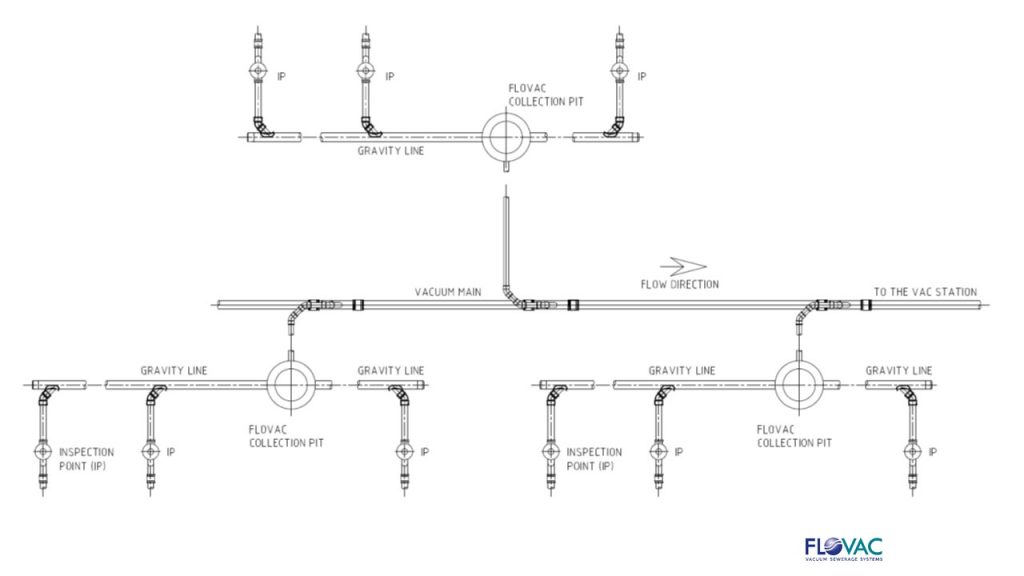

Vacuum mains are an essential component for any Flovac vacuum sewerage system. Its main function is to transport sewage and air from the collection pit to the vacuum pump station. The mains are carefully designed to ensure that the flow heads correctly towards the vacuum pump station. They are also designed to ensure that wastewater is injected at the right places within the system so as to avoid water logging.

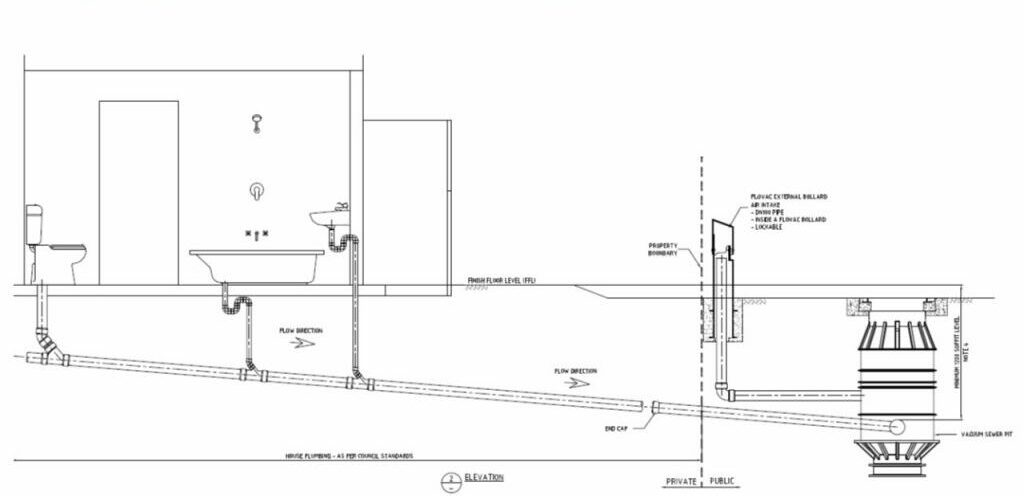

Property to collection pit gravity connection

Flovac vacuum mains, which are either PE or PVC, are designed to be as shallow in the ground as possible and are laid at a 1/500 grade. The contractor builds steps in the pipework to keep the mains from getting too deep. This makes the installation works easier, faster and cheaper as there is no need for deep trenches in the ground. The more steps that are installed, the more hydraulic losses are created, lessening the distance that the mains can go. It is important to have collection pits evenly distributed around the catchments and along the vacuum mains to ensure fast movement of sewage to the VPS.

How are the vacuum mains installed?

The first stage is connecting the gravity lines from the house to the Flovac collection pit. Usually between 4 to 6 houses are connected to a collection pit, but this depends on a few things: the ground conditions, the size of the house and the amount of flow likely to enter the sewer at this point.

It is important to lay the vacuum mains at a grade sloping downward towards the vacuum pump station. As said before, due to the negative pressure within the vacuum mains it is possible to lay the pipework at a 1/500 grade. This suggests that the system is actually a hybrid gravity system, which is true, so as to minimize energy use.

Connecting pipework from a collection pit to the vacuum main

Also, vacuum mains are laid at a depth of between 1-2 meters (3-6 feet) and do not require manholes. The steps in the mains are necessary to maintain a shallow depth. It is also important to mention that the flexibility and shallowness of all of the pipework is very useful when dealing with high water table, hard rock or acid sulfate soils. Contractors can lay pipe at a much faster pace, which minimizes disruptions to homeowners and delays in the project.

Environmental benefits

Flovac mains in a shallow trench

There is also an environmental benefit in that there is little to no impact on the water table level. Vacuum systems are considered to be the safest technology to use when dealing with environmentally sensitive areas. This is because any break in the pipework would suck air into the system as it operates under a negative pressure; therefore, there is no chance of sewage spills.

Also, due to its safety, systems are now being installed with the vacuum main being installed in the same trench as the water main as well as the force main. In the event of a leak or a blockage in any pipe of the system, the problem would be quickly discovered as the vacuum pumps would run longer to keep up the depleted vacuum.

Get our news

Temas

Archives

FLOVAC

Flovac is the world’s leading vacuum sewerage engineering, supplier and operation company.

Primer de Maig 4 Street

08980, Barcelona

Spain

CONTACT US

COPYRIGHT © 2021 FLOVAC - THE GREEN FUTURE OF SEWERAGE