Flovac Vacuum Pump Station: Parts & Components

- 4 December, 2020

¿What is a vacuum pump station and how does it work?

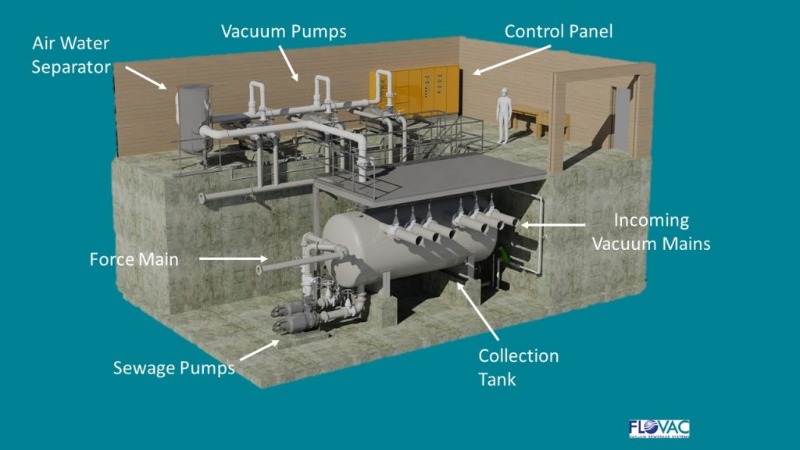

Any Flovac vacuum sewerage system is made of 3 main parts: the collection pit, the vacuum network and the vacuum pump station. This time, we will focus on the last element: the VPS.

The vacuum pump station is the station that houses the collection tank to collect the sewage, discharge pumps to send the sewage to a wastewater treatment plant (WWTP), controls to automate the station, and vacuum pumps which create a negative pressure in the vacuum mains. Let’s see with more detail each component and their functions.

Collection Tank

Although mild steel and fiberglass collection tanks have been used in the past, most tanks are now made of stainless steel 316 due to the corrosive nature of the wastewater and the location of many vacuum systems near the ocean.

Flovac Collection Tank

Collection tanks can be either vertical or horizontal, and have an operating volume as well as a buffer volume. All sewage from the vacuum network enters the collection tank, which is under a negative pressure and is held here until the tank is 1/3 full of liquid. Then, the sewage pumps will discharge the sewage to the WWTP. The remaining 2/3 of the tank, which consists of air, is used as a vacuum lung, preventing excessive starts of the vacuum pumps.

Vacuum Pumps

A standard vacuum station has 2 (1+1) vacuum and discharge pumps, which are individually capable of operating the entire system. They operate alternately (one at each time), always leaving one of them in reserve. When water and air enter the system, the vacuum level rises from -60Kpa to -50Kpa. The capacities of the vacuum pumps are calculated in such a way that they can restore the pressure from -50Kpa to -60Kpa in less than 3 minutes. The vacuum pumps are designed to operate between 2 and 3 hours a day.

Controls

The main function of the controls in the VPS is to monitor all elements in the scheme. Although Flovac supplies monitoring systems for both the vacuum network and the vacuum pump station, many clients also require an integration with their own SCADA networks. Here is some data provided by the controls at the vacuum pump station:

- Pre-programmed alarms: low vacuum alarm, flood alarm, etc.

- Information on levels: high water level in the tank, etc.

- Problems in the control equipment.

- Information on the system performance: operation hours, etc.

Vacuum Pump Station Buildings

Buildings can be designed to blend into the local area. The space required can be as small as a 10 foot container or as large as a normal house block. The stations can be both on the surface, semi-buried or completely buried.

Vacuum pump station from the outside

Flovac provides prefabricated and custom-made vacuum pump stations, depending on the land conditions, the clients’ preferences and the type of project. This way we save construction costs and time.

Get our news

Temas

Archives

FLOVAC

Flovac is the world’s leading vacuum sewerage engineering, supplier and operation company.

Primer de Maig 4 Street

08980, Barcelona

Spain

CONTACT US

COPYRIGHT © 2021 FLOVAC - THE GREEN FUTURE OF SEWERAGE