Flovactronic, Flovac's Smart Monitoring Software

- 1 February, 2021

How are vacuum sewerage systems monitored?

When installing a vacuum sewerage system, it is very important to keep track of its condition to ensure an optimal performance. Flovac, the largest designer and operator of vacuum sewerage systems, has developed its own intelligent software to manage and monitor any installation.

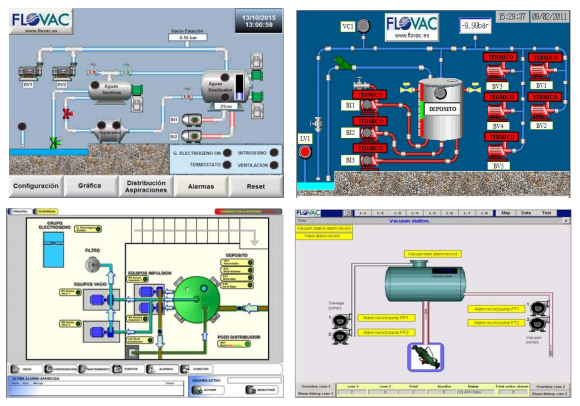

Flovactronic, the software developed by Flovac, automatically controls and monitors any vacuum sewer system. The software is responsible for performing comprehensive fault diagnostics, verifying flow infiltrations, reporting the risk of overflow, optimizing energy and adjusting the system, which results in a great reduction in maintenance costs.

Flovactronic Main Control Screen

Flovactronic can be operated by remote control. This means that operators can control any installation from either the vacuum station, the control center, the headquarters, on any device with Internet connection anywhere on the planet. Also, Flovactronic can be easily adapted to both new and already existing SCADAs.

Which sections monitors the Flovactronic software?

Flovac has developed a protocol for monitoring all aspects of a vacuum sewerage system. The monitoring takes place in two main sections: the vacuum pump station and the vacuum pipe network. Let's see with more detail each section and the data collected by the software.

Vacuum Station

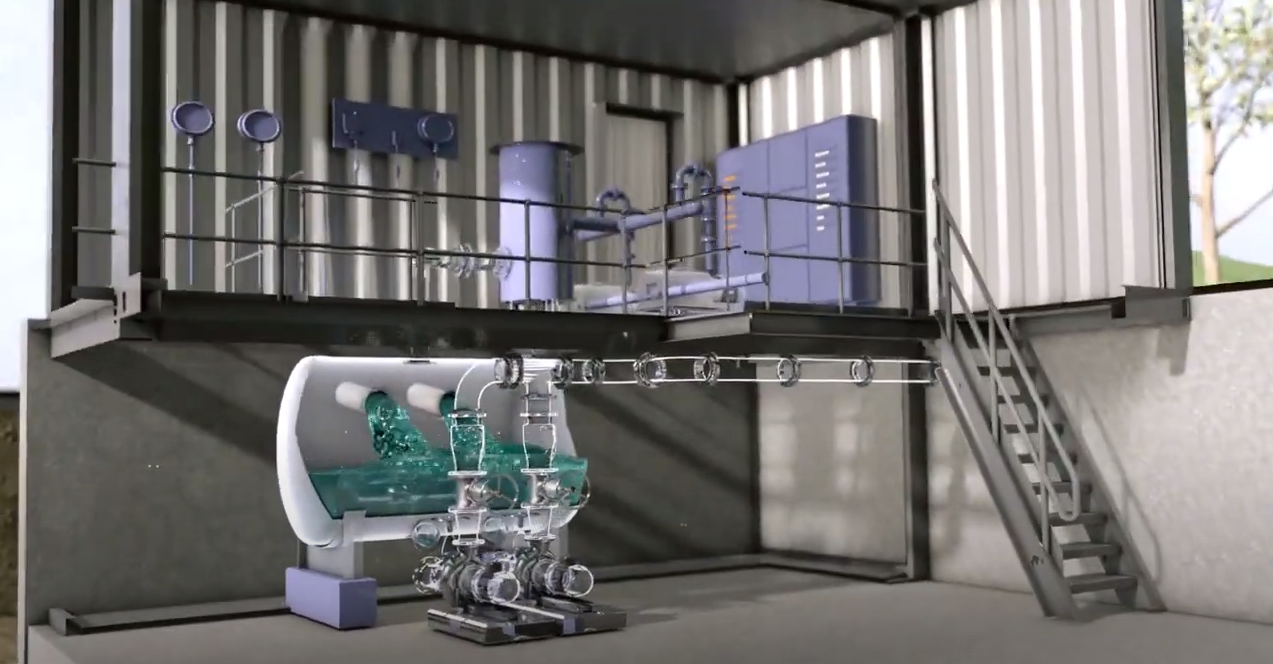

The vacuum pump station is the station that houses the collection tank to collect the sewage, the discharge pumps to send the sewage to a wastewater treatment plant (WWTP), the controls to automate the station, and the vacuum pumps which create a negative pressure in the vacuum mains.

Flovactronic collects data from the following items: the vacuum pumps, the valves, and the levels of vacuum, water in the tank and also possible flooding in the vacuum station.

Flovac Vacuum Pump Station

Flovactronic can also be customized to include more data in the main screen for the vacuum station: soft starters, variable frequency drives, flow measurement, water intrusion detection, temperature, humidity and electricity consumption, among others.

Vacuum Pipe Network

The vacuum pipe network is an essential component for any Flovac vacuum sewerage system. Its main function is to transport sewage and air from the collection pit to the vacuum pump station. The mains are carefully designed to ensure that the flow heads correctly towards the vacuum pump station.

Flovac Vacuum Pipe Network

Flovactronic can help to quickly detect leaks, blockages or floodings by monitoring the vacuum lines, the suction points and the performance of the valves. All information is displayed in real-time to optimize the global managing of the system.

Benefits of Flovactronic: customization and versatility

The main advantatge that offers the Flovac monitoring technology is that it can adapt perfectly to the specific needs of the customer and the vacuum sewerage system.

Depending on the complexity of the system, we will recommend either a basic monitoring (to only control the vacuum station) or a advanced monitoring (to control both vacuum station and pipe network). Another great benefit is the versatility of the interface, since it can be customized depending on the data that the customer wants to see.

With Flovactronic it is possible to have real-time information and to guarantee a safe performance of the system. This software can be used in any Flovac installation: residential developments, hotels and resorts, ports and marinas, industrial warehouses, supermarkets, etc. Flovactronic’s versatility and adaptability are the best guarantee of success.

Get our news

Temas

Archives

FLOVAC

Flovac is the world's leading vacuum sewerage engineering, supplier and operation company.

Primer de Maig 4 Street

08980, Barcelona

Spain

CONTACT US

COPYRIGHT © 2021 FLOVAC - THE GREEN FUTURE OF SEWERAGE