New Flovac catalog

- 20 January, 2017

New Flovac catalog available

Flovac has published a new, more complete and updated catalog of our vacuum sanitation system. The new catalog reflects the progress of the company and is a clearer and more useful tool for web visitors. Details of the Flovac vacuum sewer system and its applications can be found in the document. Click here to download it.

When and why to use a vacuum sewerage system

Flovac Pit

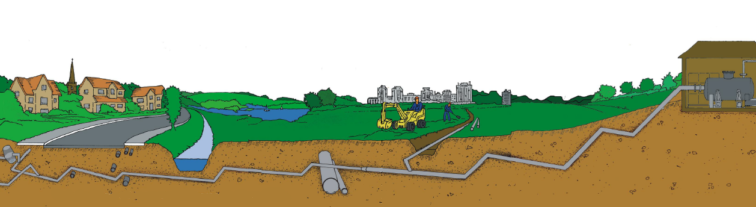

The most common sewerage systems are the gravity ones, which rely on gravity as the most economical driver to evacuate wastewater. But there are not always conditions favorable to gravity (that is, land with enough slope, land with no water table, non-rocky terrains, easily accessible land, etc.).

When these conditions do not exist, the Flovac system is the best alternative to implement and to reduce costs as well.

Unlike gravity systems, the vacuum system can adapt perfectly to the natural conditions of the terrain, requiring only a narrow and shallow trench for the installation of the network, and thus drastically reducing the cost of investment.

Main advantages of the Flovac system

Easy installation. Vacuum pipes have a small diameter and are installed on shallows trenches. Also, power is required only at the pump station, thus reducing overall power costs versus gravity systems. Plus all components are supplied at site and are installed by Flovac professional operators.

Low cost. Narrow and shallow trenches are enough to install vacuum pipes, thus saving high expensive shoring and rock diggings. There are no grinder pumps required for distant

points as well (power is only required at vacuum station). Also, prefabricated vacuum stations, preassembled pits and suck-outs save execution costs and reduce execution times.

Imperceptible. Vacuum high speed on pipework is the warranty to avoid clogging lines. There are no odors, noises or any other discomforts at any part of the system.

Reliable. All the components and materials of the system pass the most exhaustive controls to comply with current regulations. Also, all the components in contact with water are made of thermoplastic or stainless steel.

Safe. There isn’t any chances of sewage spills as all pipework operates under a negative pressure. The sealing at the vacuum net guarantees that no sewage will leak out into the environment.

Get our news

Temas

Archives

FLOVAC

Flovac is the world’s leading vacuum sewerage engineering, supplier and operation company.

Primer de Maig 4 Street

08980, Barcelona

Spain

CONTACT US

COPYRIGHT © 2021 FLOVAC - THE GREEN FUTURE OF SEWERAGE