Vacuum vs. Gravity Sewerage Systems

- 4 November, 2020

Sewerage systems comparison

Vacuum sewage systems are the best option for geographic areas with special conditions or environmentally sensitive areas. This system uses differential air pressure and gravity to rapidly transport sewage in a network of essentially empty pipes from collection pits to a central collection tank. A batch of sewage enters the vacuum system when the atmospheric Flovac valve opens in a collection pit and the sewage is sucked into the vacuum main. The Flovac valve remains open briefly following the removal of the sewage from the pit, allowing atmospheric air to enter the suction pipe and blow the sewage batch toward the vacuum pump station (and later, to a discharge point).

Flovac pit and vacuum valve

Its main advantage is that, due to its characteristics, it can be used in situations where the conventional system (the gravity one) cannot be installed. This would be: on unstable soils, on flat lands where there is no natural slope, in areas with a high water table, on rocky terrains, in sensitive ecosystems and in places with difficult access due to existing constructions. Flovac offers the most efficient solution for these situations since the gravity system does not guarantee the protection of those areas, as it can be polluting.

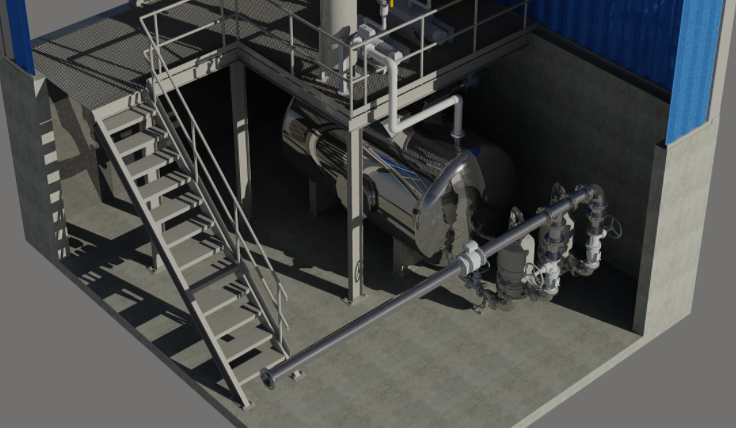

Vacuum sewer systems

Vacuum systems require less construction works since the pipe network can be installed at a superficial level (which means less excavation costs and less construction time). Also, power is required only at the pump station. A single pump station is usually all that is required to cover a large area (more than 3 km), without needing intermediate pumps. In the event of clogged pipes, wastewater backflow can't reach the houses thanks to the vacuum valves.

Flovac pipe network

Since vacuum is maintained within the mains at all times, there is no chance of exfiltration of sewage or infiltration of ground water. Operators are immediately alerted of a leak in the main due to longer vacuum pump run times, so it can be found and repaired pretty quickly. If service is required, a single operator takes on average 10-15 minutes to complete any task. No special equipment is required. Lastly, there are no bad odors with vacuum systems.

Gravity sewer systems

Gravity systems require larger construction works since the pipes are bigger and need to be installed in deeper trenches. Therefore, they are more expensive and take longer to install. Also, in flat terrains, this system requires electricity at the pump station (and many pump stations may be required to service a single catchment).

Another thing is that broken pipes can go unnoticed for many months because they are installed in deep trenches as mentioned before. This complicates the repair process and makes it more expensive. As for the maintenance of the system, there are high long term costs due to multiple pump stations and deep gravity mains. Lastly, bad odors can occur, specially in flat lands.

Flovac, the most sustainable solution

In gravity systems, as mentioned before, spills are difficult to identify due to the depth at which the pipes are buried. Therefore, it takes longer to fix leakage problems. The consequences of unnoticed leaks can be very damaging and dangerous, for instance, ground subsidence or pollution of the area with wastewater. Also, repair works are quite expensive.

However, with vacuum systems this cannot happen. In the event of pipeline damage, the vacuum station would detect a drop in the vacuum level and give the corresponding alarm in less than 10 minutes. Flovac's smart monitoring software would inform the operator of any problems, such as infiltration or illegal stormwater connections from the homeowner, the energy efficiency of the system through its use of air, and any blockages or failures that may occur.

Sealing at the pipe network

Also, as all pipework operates under a negative pressure, any break in the net would suck air into the system (which is easy to repair). This reduces any environmental risks, therefore making Flovac the most suitable and sustainable sewerage solution.

Get our news

Temas

Archives

FLOVAC

Flovac is the world's leading vacuum sewerage engineering, supplier and operation company.

Primer de Maig 4 Street

08980, Barcelona

Spain

CONTACT US

COPYRIGHT © 2021 FLOVAC - THE GREEN FUTURE OF SEWERAGE